Related Products

Introduction to Hardware Springs

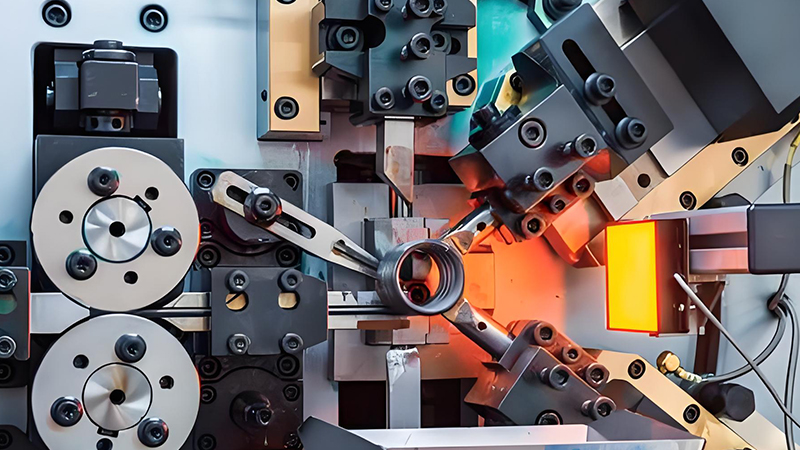

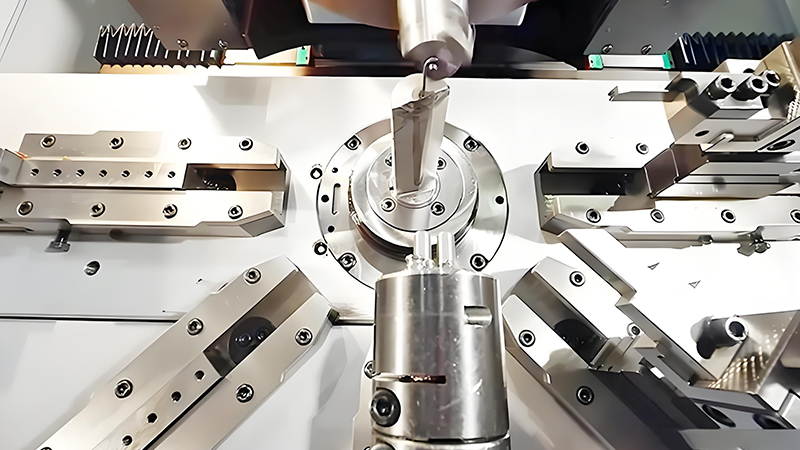

A spring is a mechanical component that uses elasticity to work. Parts made of elastic materials undergo deformation under external force, and after removing the external force, they return to their original state. Also known as "spring". Generally made of spring steel. The types of springs are complex and diverse, divided by shape, mainly including spiral springs, scroll springs, plate springs, irregular springs, etc.

According to the nature of the force, springs can be divided into tension springs, compression springs, torsion springs, and bending springs. According to the shape, they can be divided into disc springs, ring springs, plate springs, spiral springs, truncated scroll springs, and torsion bar springs. According to the production process, they can be divided into cold coil springs and hot coil springs. Ordinary cylindrical springs are most widely used due to their simple manufacturing and the ability to be made into various types according to load conditions, as well as their simple structure. Generally speaking, the manufacturing materials of springs should have high elastic limit, fatigue limit, impact toughness, and good heat treatment performance. Commonly used materials include carbon spring steel, alloy spring steel, stainless spring steel, as well as copper alloy, nickel alloy, and rubber. There are two manufacturing methods for springs: cold coil method and hot coil method. Spring wire with a diameter less than 8 millimeters is generally rolled by cold rolling method, while those with a diameter greater than 8 millimeters are rolled by hot rolling method. Some springs require strong pressure or shot peening treatment after production to improve their load-bearing capacity.

Previous: No More