Related Products

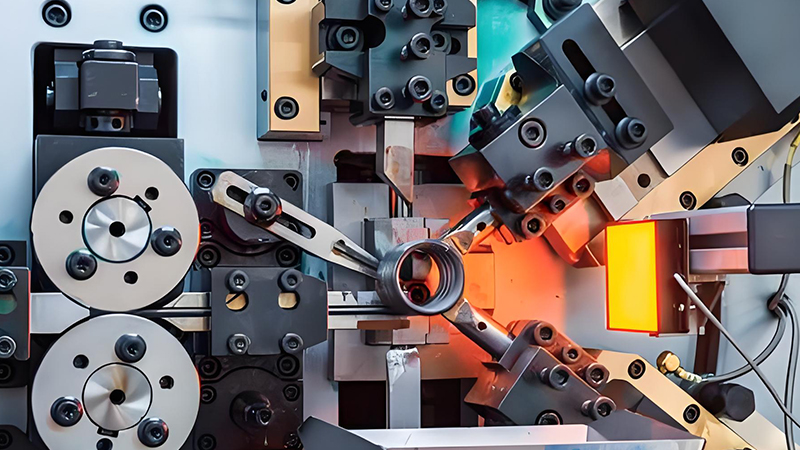

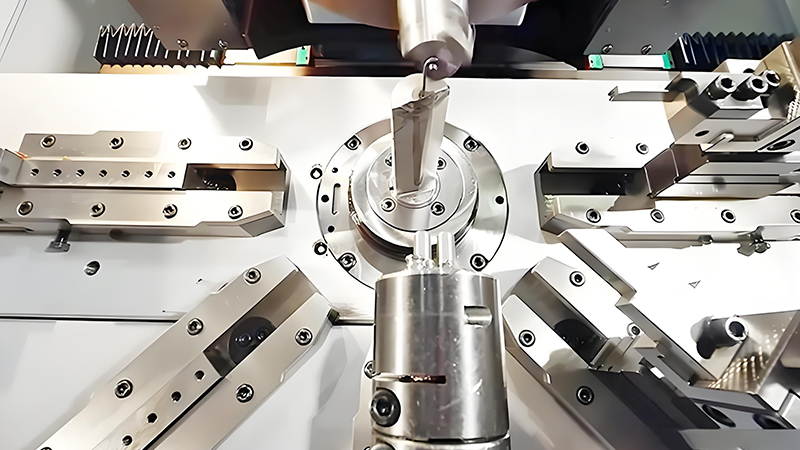

Overview of Spring Processing Technology

1、 The basic process of spring processing

1. Stretch: Stretch refers to a processing method in which metal materials are processed through specialized stretching machines to produce tensile deformation, resulting in a smaller cross-sectional area and an increase in length. In spring processing, stretching is one of the commonly used processing techniques, which can be used to produce linear springs, spiral springs, etc.

2. Winding: Winding refers to the process of installing a metal wire cylinder on a spring machine, and processing it through a forming mold to form a spiral or other various shapes of springs. Winding processing is usually suitable for manufacturing spiral springs, torsion springs, torsion springs, etc.

3. Pressing: Pressing refers to the process of placing metal materials on a pressing machine and applying force through a pressing mold to press the metal materials into the desired shape. In spring processing, compression processing is often used to produce compression springs, flat springs, etc.

4. Cutting: Cutting refers to the processing method of cutting metal wires or metal sheets to a certain length through a cutting machine. In spring processing, shear processing is usually used to manufacture accessories such as stabilizer rods.

5. Welding: Welding refers to the processing method of heating and applying pressure or adding metal materials to fuse two or more metal materials together. In spring processing, welding is commonly used to manufacture double headed springs, hook springs, etc.

2、 Applicable scope and characteristics of different processing techniques

1. Stretching processing is relatively simple, requires less equipment and tools, and is suitable for producing various types of linear springs, spiral springs, etc., but has lower processing accuracy.

2. Winding processing is commonly used in the production of spiral springs, torsion springs, etc., with high processing accuracy but also high requirements for equipment and molds.

3. Compression machining is suitable for manufacturing compression springs, flat springs, etc., with relatively high machining accuracy but requiring significant pressure and molds to meet the requirements.

4. Shear processing is mainly used for producing spring accessories, which is simple to process but has relatively low processing accuracy.

5. Welding processing is usually used to manufacture double headed springs, hook springs, etc. It has the advantages of high welding strength and strong joints, but the requirements for equipment and tools are high, and the skill level of workers is also required.

In general, the commonly used methods for spring processing include stretching, winding, pressing, shearing, welding, etc., which have their respective applicable ranges and characteristics. It is important to choose the appropriate processing technology according to specific needs.